Tire Repair Q&A: Vulcanizing Patches and Plugs

Vulcanization 101

Vulcanization is a chemical process for hardening rubbers (such as tire rubber). The most common vulcanizing method is to treat natural rubber with sulfur, which causes a chemical reaction that softens the touching materials (such as a patch and a tire) and binds them together, increasing the rubber’s rigidity and durability.

Tire Patches

Slime tire patches come pre-treated to vulcanize with a tire or tube. When the glue or rubber cement is added, it creates the chemical reaction that heats the material and adheres it to the tire or tube. The rubber cement itself does not need to be “vulcanizing.” Regular rubber cement will work as a vulcanizing agent and create an effective seal between the rubber and the patch.

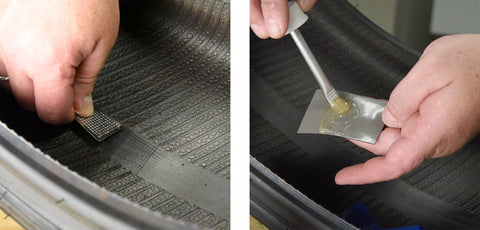

Slime’s tips for a strong patch adhesion include:

- Scuff the area on the tire or tube before applying the rubber cement. Because the product is melting to the tire, having a scuffed area increases the patch’s ability to adhere

- Make sure all edges are securely bonded with the tire or tube before adding air

- For longer term performance, especially with tubes, Slime recommends creating a “sandwich” between the tire casing and the pressure from the tube to increase the patch’s effectiveness

Tire Plugs (also called Tire Strings)

For as long back as we can remember, tire plug kits have come with a small bottle of rubber cement. While the glue may aid in installation (acts as a lubricant), the rubber cement added to the product does not actually add value in sealing up the puncture.

Unlike the vulcanization of a patch to a tire, tire plugs rely on the general pressure of the tire hole pushing on the plug to create a compression seal, rather than a chemical seal. Glue is a hazardous material, and not necessary for the tire plugs to work, so we expect to see more tire plug kits come without glue in the future.

Do-It-Yourself Tire Repair

Interested in plugging or patching your own tire? Check out our resources: